GANBA HOLDS

How can climbing holds be designed and produced more sustainably? Because current climbing holds are made out of composite materials and aren't recyclable.

In collaboration with the climbing community, I have answered this question through various proposed solutions.

I consulted with the different parties that are involved with climbing holds. From the manufacturer (blocz), the setters to the climbers that touch the holds in the end.

I experimented and developed different manufacturing processes and typologies to make climbing holds on one hand more sustainable but on the other more intriguing, usable and flexible.

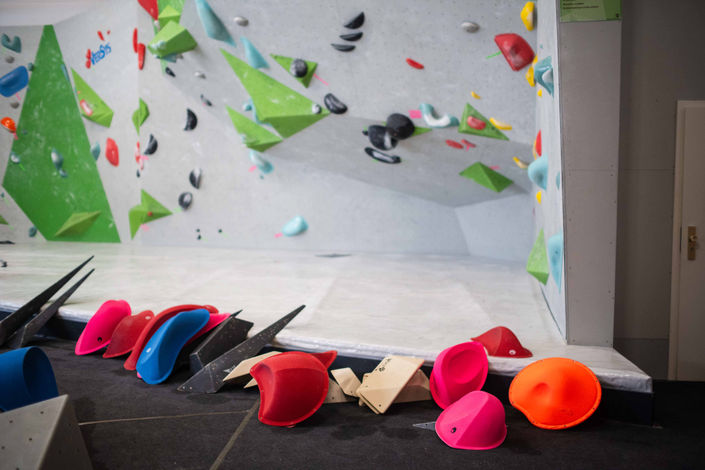

I developed climbing holds out of: wood, rPETG, rPLA, PHA, rABS, aluminium foam, rubber, more sustainable PU and ceramic.

The resulting holds were tested in my local climbing gym, Greifhaus in Braunschweig, Germany. There I let the route setters play and experiment with the different holds. The result were two routes, one of them was tested for a few weeks in the commercial setting.

A tausend thanks to: Greifhaus, Fliegerhalle, Blocz, BASF, Alupor and Recycling Fabrik for the extensive support with my bachelor project!